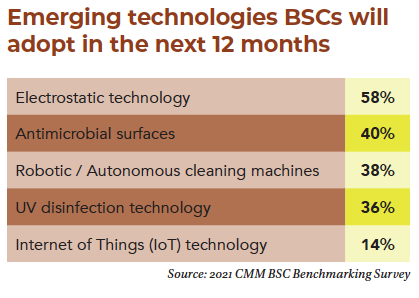

During the COVID-19 pandemic we’ve seen a burst of new products and technologies for professional cleaning and disinfecting come to market. Many cleaning operations are adopting new technologies to achieve higher levels of cleaning and to show their customers they are committed to using the latest advances to ensure clean, safe, and healthy indoor environments. In our annual benchmarking survey of building service contractors (BSCs), CMM asked which emerging cleaning technologies BSCs plan to adopt in the next 12 months. Here, we round up the top five of those technologies, from electrostatic sprayers to antimicrobial surface protectants, and detail what you should know before you use them.

Electrostatic technology

Electrostatic spraying, in particular, has drawn increased interest throughout the pandemic because of the need to disinfect large indoor spaces—schools, offices, businesses—or areas with many surfaces.

The electrostatic disinfectant sprayer has become a pandemic bestseller of sorts. According to the Global Electrostatic Disinfectant Sprayer Market report published in September 2020, this market is likely to exceed US$1.9 billion by 2025. The market by revenue is expected to grow at a compound annual growth rate (CAGR) of approximately 14% during the period of 2019–2025.

“Although the demand for disinfectant sprayers has traditionally remained moderate, the post-COVID-19 pandemic unlocks the market and preference for electrostatic sprayer systems in several end-user applications,” the report stated. “Educational centers, travel and transport offices, health care centers and hospitals, sports and recreational facilities, industrial and commercial spaces, food services, and hospitality sectors are the major end-use applications.”

More than half (58%) of 185 BSCs who responded to the 2021 CMM BSC Benchmarking Survey conducted in August say they plan to adopt electrostatic technology in the next 12 months.

How it works: An electrostatic sprayer applies a small electrical charge to aerosols passing through its nozzle. These charged droplets easily adhere to environmental surfaces. Surfaces must be cleaned before the disinfectant mist is applied with an electrostatic sprayer for the disinfectant to

be effective.

Sprayer types range from handheld units and self-contained backpacks to variations of rolling cart systems, or a combination of the two. Some sprayers are battery-powered, while others are corded, but both are designed to positively charge the liquid solution.

The benefits: Electrostatic sprayers can be used to apply disinfectants to all types of surfaces—walls, floors, counters, chairs, and tables—and even fabrics and plastics. They can also offer better surface coverage—some say by 50%—over traditional disinfection methods, such as wipes, trigger sprayers, or mops. They can apply chemicals in a more efficient, controlled manner and help avoid liquid pooling often associated with trigger sprayers.

What to know: “The U.S. Environmental Protection Agency (EPA) considers electrostatic sprayers ‘low-pressure sprayers,’” explained Liz Caracciolo, chief operating officer of OpenWorks, a national facilities management company headquartered in Phoenix. “Any disinfectant labels that include the language ‘low-pressure sprayer’ or ‘low-pressure coarse sprayer’ indicate that the product can be used through an electrostatic sprayer. While this is an effective tool for disinfecting possibly the broadest range of surfaces, training is required to ensure comprehensive coverage and results.”

Outlook: The Global Electrostatic Disinfectant Sprayer Market report shows the demand for backpack sprayers is gaining traction owing to their portable design and ease of application with high efficiency. It also finds the sales volume in the post-COVID-19 outbreak has increased in end-user industries such as hospitality, education,

and restaurants.

Antimicrobial coatings/surface protectants

Long used in the health care industry to prevent the spread of health care-acquired infections (HAIs) and in the food and beverage industry to keep production lines pathogen-free, antimicrobial coatings and surface protectants are now becoming mainstream in the cleaning industry too thanks to innovations spurred by the coronavirus pandemic.

Significant technology advances have led to innovative antimicrobial products positioned in the market as “self-cleaning” and “self-disinfecting.”

How it works: Antimicrobial surface protection products sprayed or wiped on a surface provide protection against germs, bacteria, mold, mildew, and fungi.

“Once applied to a disinfected surface and allowed to dry, the solution creates a covalent bond that has a unique spiked structure and a positive electrical charge. On contact, the spikes punch through the cell walls of the microbes,” Caracciolo explained.

The benefits: Antimicrobial surface protectant can be applied to many types of surfaces, including flooring, walls, doors, desks, and electronics such as phones and computer keyboards. Many of these products claim to stop the spread of pathogens that can cause disease for up to 90 days.

What to know: Antimicrobial surface protection is not a substitute for regular cleaning practices, including disinfecting, however it can help reduce the spread of germs and bacteria between cleanings. It’s also important to note that not all long-lasting antimicrobial surface protectants contain List N EPA-approved disinfectant, which is proven to be effective against the SARS-CoV-2 virus that causes COVID-19.

Outlook: Polaris Market Research forecasts the global antimicrobial coatings market to grow at a CAGR of approximately 6% during 2020–2026.

About 40% of BSCs say they plan to adopt antimicrobial surface technology in the next 12 months, according the 2021 CMM BSC Survey.

Caracciolo said her company has started using an antimicrobial spray product that combines a List N EPA-approved disinfectant with surface protectant. The product uses a patented application process of first cleaning, then disinfecting, then protecting the surface with the goal of providing a longer-lasting surface defense compared to cleaning and disinfecting alone.

Robotic/autonomous cleaning machines

While the cleaning industry was already warming up to the idea of robotic cleaners before the pandemic, the increased health and safety concerns, rising labor costs, and limited resources brought on by COVID-19 has sped up the demand and implementation of this technology.

The 2021 CMM BSC Survey found 19% of BSCs currently use autonomous/robotic equipment, up from only 10% in 2020. Those who report they don’t currently use this equipment but are considering it jumped from 17% in 2019 to 29% in 2020. Nearly the same number (27%) of BSCs this year said they were considering implementing robotic equipment.

Floor scrubbing robots topped the list of autonomous equipment BSCs said they were likely to implement (29%) followed by vacuum sweepers (19%).

How it works: Self-driving, programmable floor scrubbers, for example, use built-in cameras and sensors that integrate with intuitive software platforms to safely navigate surroundings, detect and avoid people and obstacles, and learn new routes. Sensors collect real-time data that can alert managers when cleaning tasks are complete, tanks need refilling, or maintenance is required.

The benefits: A major selling point of cleaning robots during the pandemic is how these machines can take on repetitive, labor-intensive cleaning tasks like vacuuming and floor scrubbing, which allows employees to focus on “high-value” tasks like disinfecting surfaces. In addition to this labor reallocation and the increased productivity that comes with it, equipment manufacturers say cleaning robots can offer increased measurability of cleaning efforts, reduced costs, enhanced customer/employee experience, and visible proof that the business is keeping pace with innovation.

What to know: Robotic cleaning machines aren’t fit for every company or facility nor will they replace the need for human workers. Consider your facility’s layout and size and the impact these robots will have on your staff. Staff will need not only startup training but also ongoing education on how to operate these machines.

Outlook: The next wave of cleaning robots coming to market today are multifunctional, meaning they can disinfect doorknobs or stock shelves—depending on your facility—at the same time they clean your floors.

For example, last year Nilfisk introduced a new ultraviolet germicidal irradiation (UVGI) light attachment for its Liberty SC50 autonomous scrubber. This past September, Canadian-based Avidbots announced a new disinfection sprayer add-on for the company’s floor-scrubbing

robot Neo.

“With the Disinfection Add-On, our customers can disinfect surfaces for a few hundred dollars per month—this is more than 10 times [the] savings when compared to having a separate robot or human completing the same task,” said Avidbots chief technology officer and co-founder Pablo Molina.

Ultraviolet (UV) disinfection technology

Although ultraviolet light has been used extensively for more than 40 years to disinfect drinking water, wastewater, air, pharmaceutical products, and surfaces against many human pathogens, like other disinfection technologies it has seen a surge in popularity during the pandemic. Research has shown the wavelength range of UVC light (200-280 nanometers) is the most effective in inactivating bacteria and viruses.

There are three primary ways of applying UVC for air and HVAC surface protection against germs: upper-air, HVAC surface/coil irradiation, and HVAC airstream disinfection. Upper-air systems are typically installed in health care facilities—such as above patient beds, in waiting rooms, corridors, and break areas—where they kill airborne microorganisms. Coil irradiation and airstream disinfection systems are installed within air handling units or HVAC systems.

How it works: In health care facilities, UVC is generally used to disinfect surfaces. The wavelength of light breaks down microorganisms by naturally damaging their DNA and RNA, rendering them unable to replicate. The radiation must be contained in a device, such as a light box, robot, or tower. People must leave the room before the device is turned on because the UV rays can be harmful to eyes and skin.

The benefits: The International Ultraviolet Association (IUVA) believes that UV disinfection technologies can play a role in a multiple barrier approach to reducing the transmission of SARS-CoV-2. All bacteria and viruses tested to date (many hundreds over the years, including other coronaviruses) respond to UV disinfection, according to the IUVA. Therefore, UVC disinfection is very effective at killing pathogens when used properly.

What to know: UVC disinfection does not replace cleaning since surfaces need to be free of any soil for the UV light to touch and disinfect them. Therefore, UVC light should be used in combination with other cleaning procedures for infection control.

Installing permanent UVC lights or determining the placement of mobile devices is also a complicated process. Systems can be very costly, limiting the ability of some facilities to afford this disinfection option.

“While this technology can be effective, often workspaces need to be retrofitted to accommodate incorporating UV technology, which can be cost prohibitive for many businesses,” Caracciolo said. “However, new technologies are emerging to bridge that gap, including light bulbs that perform the same role without having to install specialty electrical devices.”

Outlook: There is movement to make UV light disinfection technology safer for use around people. Global visual technology company Christie announced in October the mass production of its CounterAct line of commercial high-ceiling light fixtures that use a patented UV lamp technology and “can be used automatically and continually in the presence of people,” according to the company.

Internet of Things (IoT) technology

When we think of Internet of Things (IoT) technology, we now think of “smart” technology like the smart speakers and thermostats we have in our homes. Connected devices that use sensors and software to share data with other devices over the internet is commonplace today compared to a decade ago.

In the cleaning industry, IoT technology is prevalent in a variety of devices and machines used in daily operations including chemical dispensers, restroom soap and paper towel dispensers, robotic floor scrubbers, and vacuum sweepers.

How it works: Sensors and processors collect and analyze data acquired from their environments. These devices share the data by sending it to a gateway or to other IoT devices. It then can be either sent to and analyzed in the cloud or analyzed locally. In a nutshell, IoT devices can gather, share, and analyze information and create actions accordingly.

The benefits: IoT devices offer many advantages to cleaning businesses including resource and cost savings, increased productivity, better cleaning results, and greater insights into their operations.

What to know: Given the amount of data generated by IoT devices, data privacy and security are among the major concerns with regard to IoT adoption, according to research firm Statista. Once devices are connected to the internet, they become vulnerable to possible security breaches in the form of hacking, phishing, etc.

Outlook: Statista predicts that by 2025, there will be more than 75 billion IoT-connected devices in use worldwide. This would be a nearly threefold increase from the IoT-installed base in 2019.

Airports and stadiums are some facilities leveraging IoT for cleaning purposes. For example, many of these high-traffic facilities are using smart monitoring systems connected to soap and paper towel dispensers in restrooms to alert custodians when supplies are low and need to be restocked.

Future considerations

While artificial intelligence (AI) is on the list of emerging technologies, only 9% of BSCs say they plan to adopt AI in the next 12 months. But like IoT, AI has already made its way into the cleaning industry. For example, if you employ an autonomous vacuum sweeper or floor scrubber, there is a good chance it runs on an AI operating system.

The pandemic has spurred cleaning technology development like never before. The new options are exciting and many are proving to have staying power because of the efficiencies and cost-savings they bring.

“When vetting new technology, always consider its complexity and any investments you will need to make to ensure its effective use; its track record compared to other technology; and finally, both the short- and long-term costs that will come from integrating the technology into your day-to-day cleaning and disinfecting regimen,” Caracciolo said.